Container Ventilation Systems: Preventing Moisture and Mold Buildup

Storage containers and trailers are essential for businesses and individuals in New England who need secure, weather-resistant storage for tools, equipment, inventory, and household goods. However, while these containers provide excellent protection against the elements, they can also trap moisture inside. This can easily lead to serious problems like condensation, mold growth, and rust. Without proper ventilation, the internal environment of a storage container can quickly become a breeding ground for moisture-related damage, ruining valuable stored items.

To prevent these issues, it’s important to understand why moisture accumulates in storage containers, the risks of poor ventilation, and how container ventilation systems can keep stored items dry and protected. Read on to learn more from Page Street Leasing.

Understanding Moisture and Mold Risks in Storage Containers

Why Moisture and Mold Accumulate

Moisture buildup inside storage containers is a common problem, particularly in New England where the weather can shift dramatically between seasons. When warm air inside the container cools rapidly—such as during chilly nights following warm days—condensation forms on the walls and ceiling. This phenomenon, known as the dew point effect, causes moisture to collect, leading to damp conditions inside the container.

In addition to temperature fluctuations, high humidity levels can also introduce excess moisture. If a storage container is in an area prone to rain or humidity, water vapor can enter the container and get trapped, leading to an increased risk of mold and mildew growth. Even items placed inside the container can contribute to moisture problems.

Another significant factor is container placement. When a container sits directly on the ground, moisture from the soil can seep into the base, contributing to condensation inside.

The Impact of Poor Ventilation

Without adequate ventilation, moisture can wreak havoc on stored goods. Condensation droplets that form on the ceiling may drip onto items below, leading to water damage. For materials like cardboard boxes, fabrics, or paper documents, this can result in irreversible deterioration.

Mold and mildew thrive in moist environments, and once they begin to spread, they can be difficult to remove. Mold growth can destroy wooden furniture, cause musty odors, and even pose health risks. Metal tools, machinery, and storage racks are also at risk, as prolonged exposure to moisture leads to rust and corrosion. Over time, these issues can cause expensive damage, requiring costly replacements or repairs.

Some of the most common problems caused by poor ventilation include:

- Water Damage – Condensation leads to dampness, warping, and deterioration of stored items.

- Mold and Mildew Growth – Thrives in humid conditions, ruining textiles, paper goods, and furniture.

- Corrosion and Rust – Affects tools, machinery, and metal structures, reducing their lifespan.

- Musty Odors – Makes the storage environment unpleasant and may be difficult to eliminate.

- Health Risks – Mold spores can trigger allergies, asthma, and respiratory problems.

- Pest Infestation – Damp environments attract insects and rodents, further damaging stored goods.

Types of Container Ventilation Systems

Choosing the right ventilation system depends on your climate, the duration of storage, and the sensitivity of stored items. There are two primary types of container ventilation: passive ventilation and active ventilation.

Passive Ventilation

Passive ventilation relies on natural airflow to prevent moisture buildup inside a storage container. This system doesn’t require electricity or mechanical parts, making it a cost-effective solution for many storage needs.

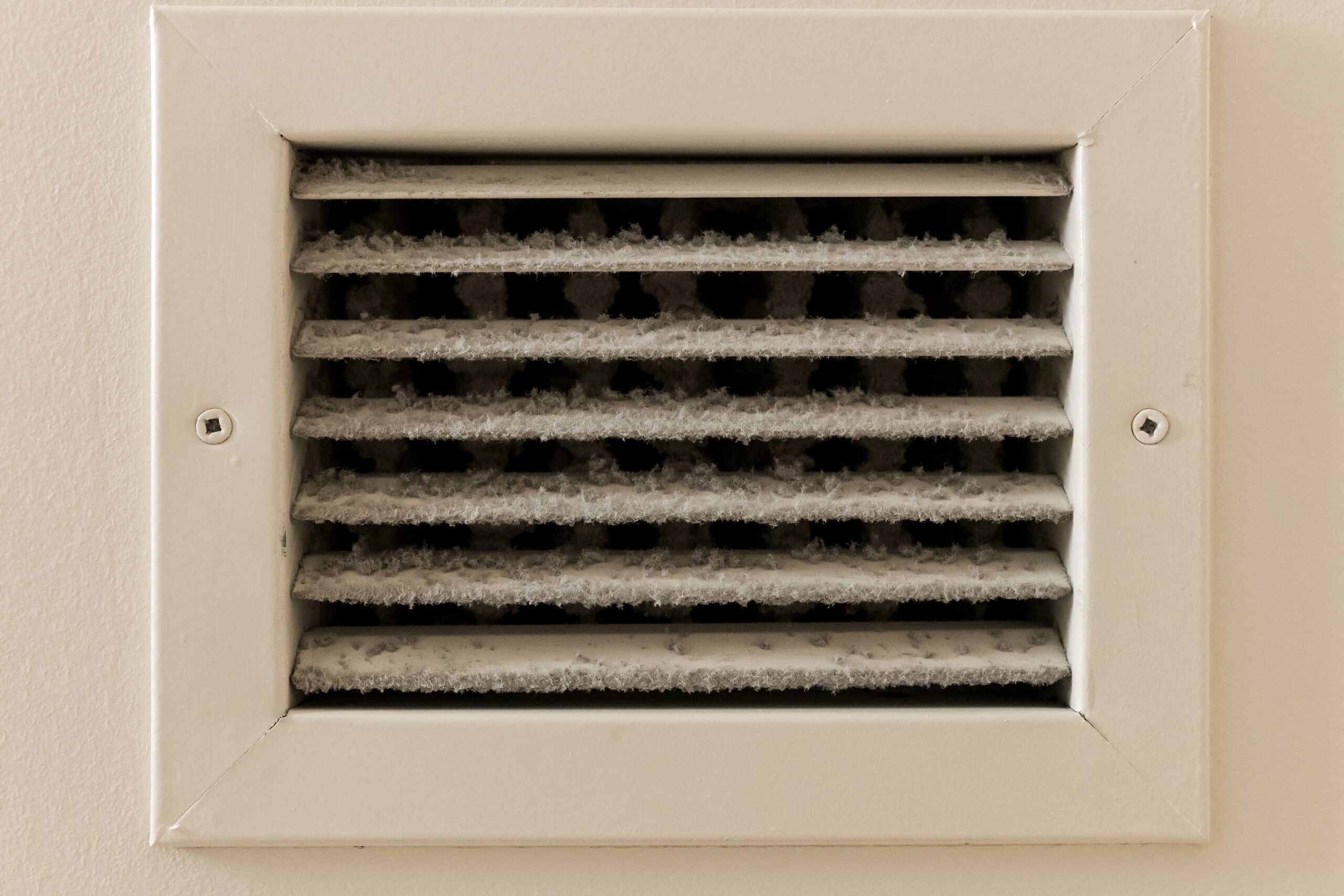

One of the most common passive ventilation methods is the installation of louvered vents. These vents are placed on opposite sides of the container, allowing fresh air to enter while expelling stale, humid air. Roof vents can also be installed to let rising warm air escape, reducing the likelihood of condensation forming on the ceiling.

Additionally, elevating the container off the ground is an effective passive moisture control method. When a container sits directly on the soil, it can absorb ground moisture, leading to higher humidity levels inside. By placing the container on wooden blocks, concrete piers, or metal beams, you can allow air to flow underneath, preventing moisture buildup from below.

Advantages of Passive Ventilation:

- Low cost and minimal maintenance

- No electricity required

- Works well in moderate humidity conditions

Active Ventilation

Active ventilation uses mechanical airflow solutions to regulate humidity and condensation more effectively. This type of system is particularly useful for containers storing moisture-sensitive materials, such as:

- Electronics – Prevents corrosion, circuit damage, and malfunctions caused by humidity.

- Textiles – Reduces the risk of mold, mildew, and fabric deterioration.

- Paper goods – Prevents warping, ink smudging, and degradation due to excess moisture.

- Wooden furniture – Protects against swelling, warping, and mold growth.

- Artwork and collectibles – Maintains proper humidity levels to prevent fading, cracking, or mold damage.

- Food products – Helps prevent spoilage and contamination in perishable or packaged goods.

- Medical supplies and pharmaceuticals – Ensures proper storage conditions to maintain product integrity.

A common active ventilation solution is the use of exhaust fans, which actively remove humid air from inside the container and replace it with fresh, dry air. Solar-powered ventilation fans are an excellent option for off-grid storage, using renewable energy to maintain consistent airflow without increasing electricity costs.

For containers located in highly humid environments, electric dehumidifiers can provide additional moisture control. These devices actively extract excess humidity from the air, helping to maintain a dry storage environment.

Advantages of Active Ventilation:

- Provides superior moisture control

- Ideal for long-term or climate-sensitive storage

- Can be adjusted based on changing weather conditions

Additional Techniques to Prevent Moisture and Mold

Dehumidifiers and Moisture Absorbers

For containers in extremely humid areas, dehumidifiers can provide additional protection. Electric dehumidifiers actively remove moisture from the air, preventing condensation and mold growth. For a low-maintenance solution, moisture absorbers such as silica gel packs or desiccant bags can be placed inside the container to help regulate humidity levels.

Proper Storage Practices

How you arrange and store items inside a container also impacts moisture control. To improve airflow:

- Avoid overpacking the container—leave space for air circulation between items.

- Place pallets on the container floor to elevate stored goods and keep them away from potential condensation buildup.

- Store items in sealed plastic bins rather than cardboard boxes, which absorb moisture.

Insulation Solutions

Insulation helps regulate temperature fluctuations, reducing the likelihood of condensation forming. Some effective insulation options include:

- Spray foam insulation – Creates an airtight barrier, preventing condensation from forming on container walls.

- Reflective bubble insulation – Reflects heat, minimizing temperature fluctuations and reducing the risk of moisture buildup.

- Rigid foam board insulation – Offers excellent thermal resistance and moisture protection, making it ideal for long-term storage solutions.

- Fiberglass insulation – While commonly used in buildings, it can be installed in storage containers for effective temperature regulation. However, it requires proper sealing to prevent moisture absorption.

Routine Inspections and Maintenance

Regular maintenance helps prevent small moisture issues from becoming major problems. Inspect your container for leaks, rust, and condensation regularly. If signs of moisture appear, identify and address the issue promptly. Check that door seals are intact, as damaged seals can allow humid air to enter. On dry, sunny days, open the container doors to allow fresh air to circulate and dry out any excess moisture.

Choosing the Right Ventilation System

When selecting a ventilation system for your storage container, consider the following factors:

- Climate: In humid regions, active ventilation or dehumidifiers are recommended.

- Stored Items: Delicate items like textiles and electronics require better moisture control.

- Storage Duration: Long-term storage benefits from insulation, passive ventilation, and moisture absorbers.

- Container Placement: Positioning the container in shaded areas and elevating it off the ground helps minimize moisture risks.

- Ventilation System Maintenance – Some systems require regular upkeep, such as cleaning exhaust fans or replacing dehumidifiers. Consider whether the container will be regularly accessed or stored off-site with limited maintenance opportunities.

- Security and Weather Resistance – Ensure that ventilation openings are properly sealed to keep out rain, pests, and debris, especially if the container is in an exposed outdoor location.

- Budget and Energy Use – Passive ventilation is cost-effective and requires no electricity, while active ventilation systems may involve additional installation and energy costs but provide superior moisture control.

Contact Page Street Leasing for New England Storage Solutions

Looking for storage containers and trailers in New Hampshire and throughout New England? Page Street Leasing offers high-quality containers and trailers to keep your stored items safe and dry.

Call us today at 603-622-1673 or request a quote.

Fill out our online contact form, and we will reach out to you ASAP.